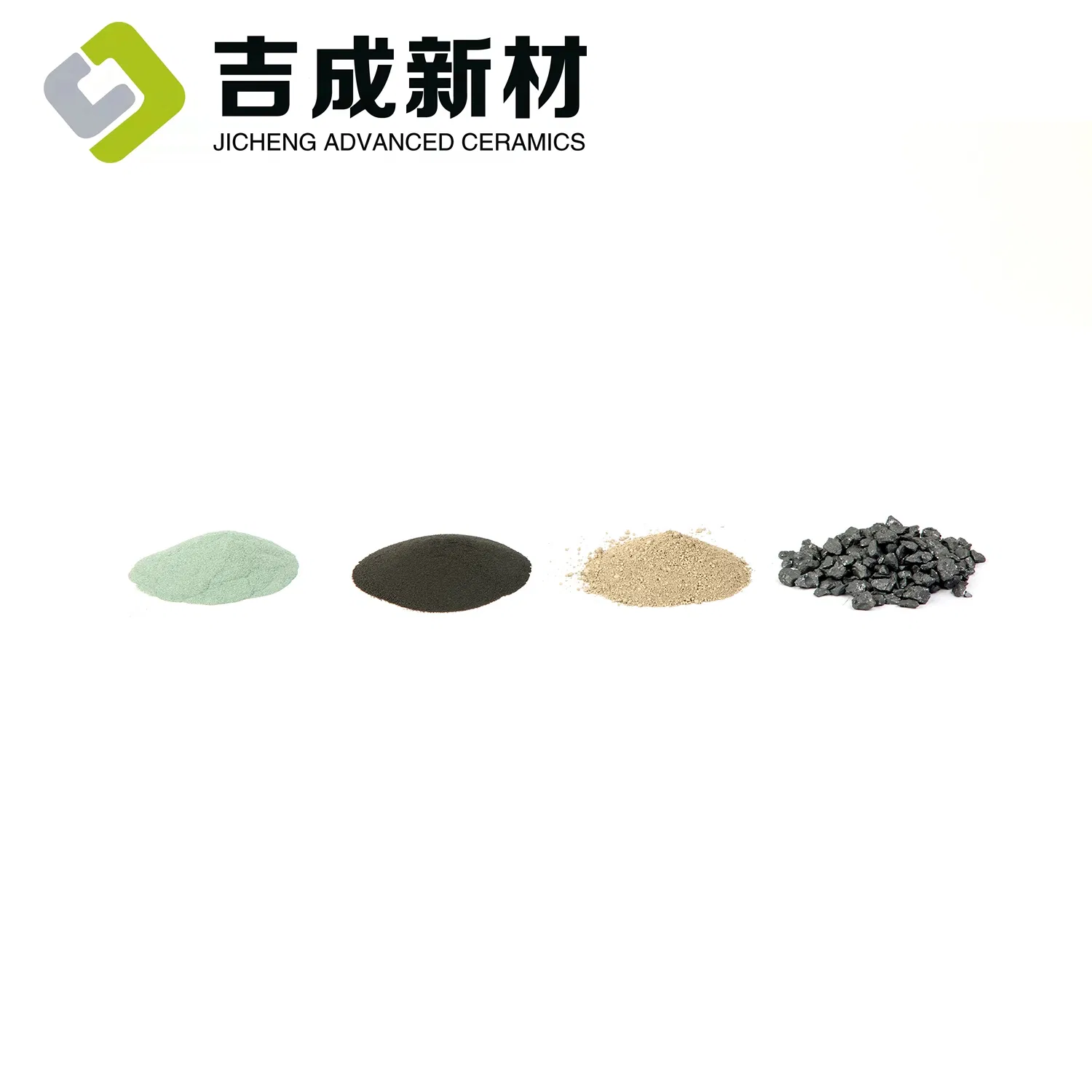

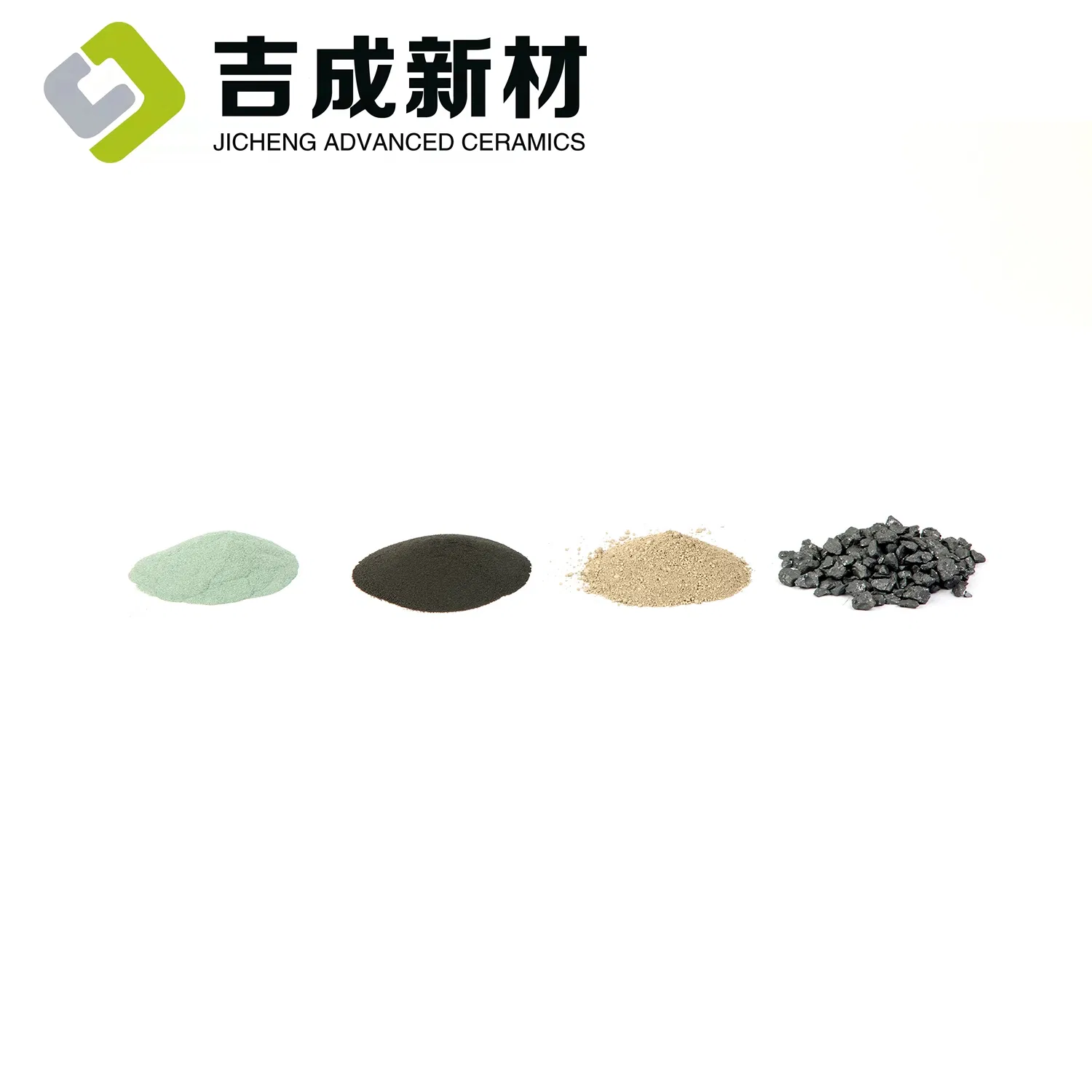

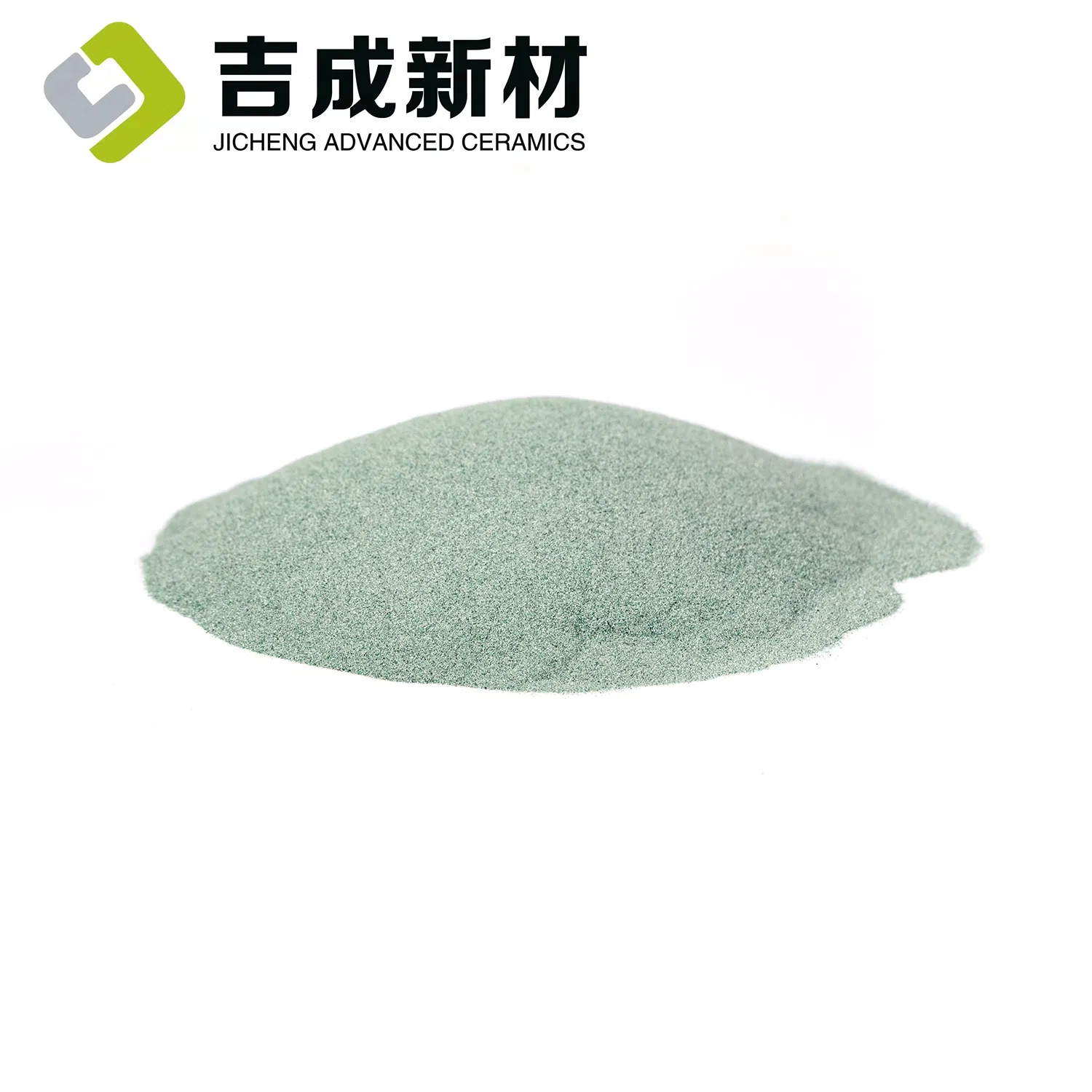

0.7um 3um Green Sic Silicon Carbide Polishing Powder

14 yrs · 50+staff · 2,700+ m²

14 yrs · 50+staff · 2,700+ m²

Find Similar Products

Product Description

High-Quality Refractory advanced Ceramics Green SiC Powder for Sale

Silicon Carbide (SiC) Green Powder, a high-purity synthetic material, excels in extreme hardness, thermal conductivity, and chemical resistance. Ideal for precision grinding, refractory ceramics, and semiconductors, it ensures durability and efficiency in high-temperature, high-stress environments. Widely used in industrial and advanced electronic applications.

1)High-Performance Protective Coatings

Reaction-bonded SiC green powder: Combines high density, exceptional mechanical strength, thermal stability , and corrosion resistance. Optimized for cost-effective sintering of complex-shaped components in aerospace, energy, and chemical industries.JCpowderR5 Unit Data Test D10 μm 0.513 qualified D50 μm 3.96 qualified D90 μm 25.096 qualified SiC % 99.41 qualified Fe2O3 % 0.025 qualified F.C % 0.02 qualified Σ.O % 0.147 qualified Jicheng Green Silicon Carbide Powder R45 Standards

JCpowderR45 Unit Data Test D10 μm 17.450 qualified D50 μm 47.959 qualified D90 μm 92.315 qualified SiC % 99.53 qualified Fe2O3 % 0.024 qualified F.C % 0.012 qualified ∑.0 % 0.029 qualified Tap density g/cm³ 2.1 qualified Viscosity mPa.s / PH 5.81 qualified Jicheng Green Silicon Carbide Powder S05 Standards

Pressureless SiC Green Powder: High-purity (>99%), thermally stable (1600°C+), corrosion-resistant. Enables low-cost, pressure-free sintering of complex parts for semiconductors, solar energy, and industrial furnaces,eco-friendly processing.

JCpowderS05 Unit Data Test D10 μm 0.197 qualified D50 μm 0.702 qualified D90 μm 1.55 qualified SiC % 99.07 qualified Fe2O3 % 0.03 qualified F.C % 0.10 qualified ∑.0 % 0.570 qualified International Standards FEPA, JIS,ANSI & Customized are available

Size D3(um) D50(um) D94 ( um) F230 53.0 ±3.0 >34 F240 44.5 ±2.0 >28 F280 36.5± 1.5 >22 F320 29.2 ± 1.5 >16.5 F360 22.8 ± 1.5 >12 F400 17.3 ± 1.0 >8 F500 12.8 ± 1.0 >5 F600 < 19 9.3 ± 1.0 >3 F800 < 14 6.5 ± 1.0 >2 F1000 < 10 4.5 ±0.8 >1 F1200 3.0 ±0.5 >1(at 80%) F1500 2.0 ±0.4 >0.8(at 80%) F2000 1.2 ±0.3 >0.5(at 80%)

JIS STANDARD Grain SizeSize DO(um) D3(um) D50(um) D94(um) #240 ≤ 127 ≤ 103 57.0 ±3.0 ≥40 #280 ≤ 112 ≤87 48.0 ±3.0 ≥33 #320 ≤98 ≤74 40.0 ±2.5 ≥27 #360 ≤86 ≤66 35.0 ±2.0 ≥23 #400 ≤75 ≤58 30.0 ±2.0 ≥20 #500 ≤63 ≤50 25.0 ±2.0 ≥ 16 #600 ≤53 ≤41 20.0 ± 1.5 ≥ 13 #700 ≤45 ≤37 17.0 ± 1.5 ≥ 11 #800 ≤38 ≤31 14.0 ± 1.0 ≥9.0 #1000 ≤32 ≤27 11.5 ± 1.0 ≥7.0 #1200 ≤27 ≤23 9.5 ±0.8 ≥5.5 #1500 ≤23 ≤20 8.0 ±0.6 ≥4.5 #2000 ≤ 19 ≤ 17 6.7 ±0.6 ≥4.0 #2500 ≤ 16 ≤ 14 5.5 ±0.5 ≥3.0 #3000 ≤ 13 ≤ 11 4.0 ±0.5 ≥2.0 #4000 ≤ 11 ≤8.0 3.0 ±0.4 ≥ 1.8 #6000 ≤8.0 ≤ 5.0 2.0 ±0.4 ≥0.8 #8000 ≤6.0 ≤3.5 1.2 ±0.3 ≥0.6

Used for surface spraying (e.g., thermal spraying and plasma spraying) on metal/ceramic substrates, creating a wear-resistant, corrosion-resistant, and high-temperature-resistant protective layer, extending the life of equipment (e.g., oil pipelines, chemical reactors, and aircraft engine components).

2) Advanced Ballistic and Human Protection

Incorporated as a reinforcement into composite materials to create lightweight bulletproof armor (e.g., bulletproof plates and helmets), leveraging its ultra-high hardness and energy-absorbing properties to protect against bullets and fragments.

3) Refractory Reinforcement

Added to refractory bricks and castables (e.g., blast furnace linings in steel mills and cement kilns), it significantly improves thermal shock resistance, high-temperature strength, and resistance to molten metal corrosion.

4) Friction Material Modification

Used in brake pads and clutch plates, its high hardness and thermal stability improve friction coefficient, reduce high-temperature decay, and enhance safety.

5) Specialty Ceramic Sintering

Used as a sintering aid or aggregate to create high-density silicon carbide ceramics (e.g., sealing rings and nozzles) suitable for extreme operating conditions (strong acids/alkalis, and ultra-high temperatures).![]()

Our Company

Zhejiang JICHENG Advanced Ceramics Co., Ltd.

Pioneering Advanced Ceramic Solutions since 2007

As a national high-tech enterprise and recipient of the Zhejiang Provincial "Specialized & Innovative" SME Award, JICHENG specializes in cutting-edge ceramic materials and system solutions for both traditional industries and global strategic emerging sectors.

Core Competencies

Innovation Ecosystem

Global Impact

Serves clients across 30+ countries in Europe, Asia, and the Americas through:

Tailored Engineering: Rapid prototyping and problem-solving for extreme operational environments (high temperature/radiation/corrosion).

Cross-Industry Synergy: Adapts military-grade ceramic technologies to civilian sectors like new energy vehicles and semiconductor manufacturing.

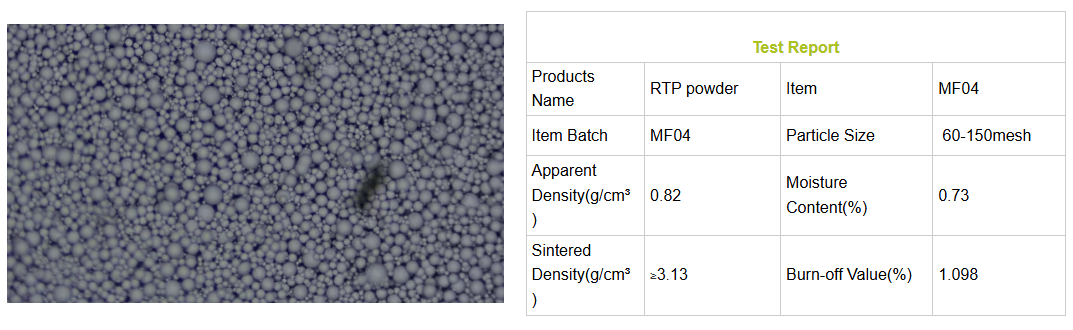

| Test Report | |||

| Products Name | RTP powder | Item | MF04 |

| Item Batch | MF04 | Particle Size | 60-150mesh |

| Apparent Density(g/cm³ ) | 0.82 | Moisture Content(%) | 0.73 |

| Sintered Density(g/cm³ ) | ≥3.13 | Burn-off Value(%) | 1.098 |

Chengdu Hongli Boya Constru…

14 yrs · 50+staff · 2,700+ m²

14 yrs · 50+staff · 2,700+ m²

Online Service

Online time: 10:00~18:00

FAQ

FAQ

Messages

Messages